Understanding Glossy Wood Cabinets: How To Degloss Wood Cabinets

Glossy wood cabinets are a popular choice for kitchens and bathrooms due to their sleek and modern appearance. However, the glossy finish can also be a source of frustration for homeowners, as it is susceptible to scratches and fingerprints. Understanding the different types of finishes and their drawbacks can help homeowners decide whether deglossing their cabinets is the right choice for them.

Types of Finishes

Glossy finishes are created using a variety of techniques, including:

- Lacquer: Lacquer is a durable and hard-wearing finish that is often used on high-end furniture. It dries quickly and produces a smooth, high-gloss finish. Lacquer is a good choice for cabinets that will receive heavy use, as it is resistant to scratches and stains.

- Polyurethane: Polyurethane is another durable finish that is often used on cabinets. It is available in a variety of gloss levels, from matte to high-gloss. Polyurethane is a good choice for cabinets that will be exposed to moisture, as it is water-resistant.

- Varnish: Varnish is a traditional finish that is made from natural resins. It is available in a variety of gloss levels, from matte to high-gloss. Varnish is a good choice for cabinets that will be exposed to sunlight, as it provides UV protection.

- Epoxy: Epoxy is a very durable finish that is often used on cabinets that will be exposed to harsh conditions. It is also a good choice for cabinets that need to be waterproof. Epoxy is typically very glossy, and it can be difficult to degloss.

Drawbacks of Glossy Finishes

Glossy finishes can be difficult to maintain, as they are prone to scratches and fingerprints. The high sheen can also make imperfections in the wood more noticeable.

- Scratches: Glossy finishes are more susceptible to scratches than matte finishes. This is because the smooth surface of a glossy finish reflects light, making any scratches more visible.

- Fingerprints: Glossy finishes are also more likely to show fingerprints than matte finishes. This is because the smooth surface of a glossy finish attracts oil and dirt from your fingers.

- Imperfections: Glossy finishes can make imperfections in the wood more noticeable. This is because the high sheen reflects light, making any irregularities in the wood more apparent.

Reasons for Deglossing Cabinets

There are several reasons why homeowners might want to degloss their cabinets.

- To reduce the shine: Some homeowners simply prefer the look of a matte finish. A matte finish is less reflective and can create a more relaxed and casual atmosphere.

- To make the cabinets easier to clean: Matte finishes are less likely to show fingerprints and scratches than glossy finishes. This can make them easier to clean and maintain.

- To hide imperfections: Matte finishes can help to hide imperfections in the wood. This is because the matte finish diffuses light, making any irregularities in the wood less noticeable.

Methods for Deglossing Wood Cabinets

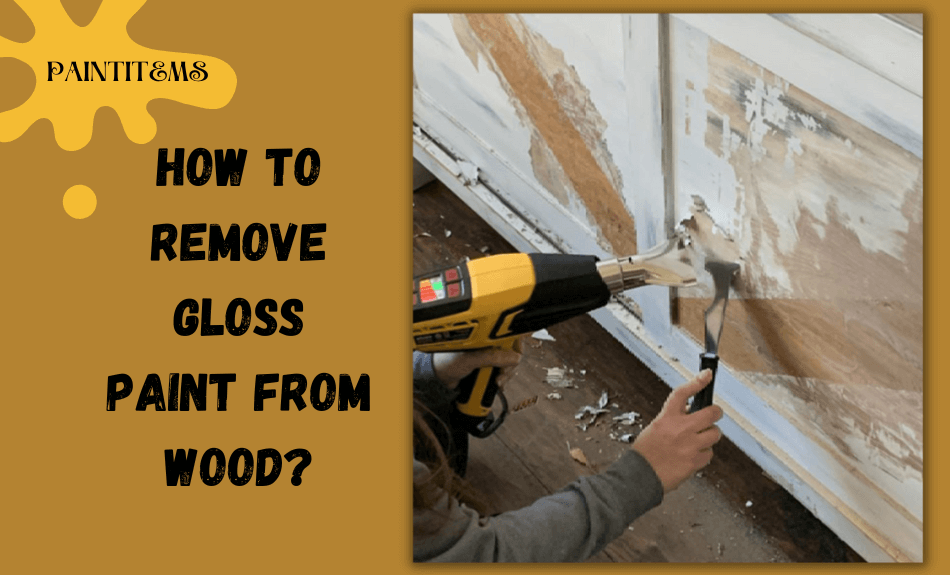

Deglossing wood cabinets involves removing the glossy finish to achieve a more matte or distressed look. This process can be accomplished using various methods, each with its own advantages and drawbacks. The two primary approaches are sanding and chemical deglossing.

Sanding Wood Cabinets

Sanding is a common and effective method for deglossing wood cabinets. It involves using sandpaper of varying grits to gradually remove the glossy layer.

Step-by-Step Guide to Sanding Wood Cabinets

- Prepare the Work Area: Clear the surrounding area and protect surfaces from dust using drop cloths or plastic sheeting. Wear a dust mask and safety glasses to protect yourself from airborne particles.

- Start with Coarse Grit Sandpaper: Begin with a coarse grit sandpaper (80-120 grit) to remove the majority of the gloss. Sand with the grain of the wood, applying gentle pressure. Avoid excessive pressure, as this can damage the wood.

- Progress to Finer Grits: Gradually move to finer grits of sandpaper (150-220 grit) to smooth out the surface and reduce sanding marks. Continue sanding with the grain, using lighter pressure as you move to finer grits.

- Finish with a Fine Grit: Finish with a very fine grit sandpaper (240-400 grit) to achieve a smooth, even finish. This step helps to eliminate any remaining sanding marks and create a more polished look.

- Clean the Surface: After sanding, use a tack cloth or damp cloth to remove any dust particles. This ensures a clean surface for subsequent steps, such as painting or staining.

Sanding Techniques for Different Levels of Deglossing

- Light Deglossing: For a subtle matte finish, use finer grits of sandpaper (220-400 grit) and sand lightly. This will remove some of the gloss without significantly altering the wood’s texture.

- Medium Deglossing: For a more pronounced matte finish, start with a medium grit sandpaper (150-220 grit) and progress to finer grits. This will create a noticeable change in the gloss level.

- Heavy Deglossing: For a distressed or heavily weathered look, use coarse grit sandpaper (80-120 grit) and sand aggressively. This will remove a significant amount of the gloss and create a textured surface.

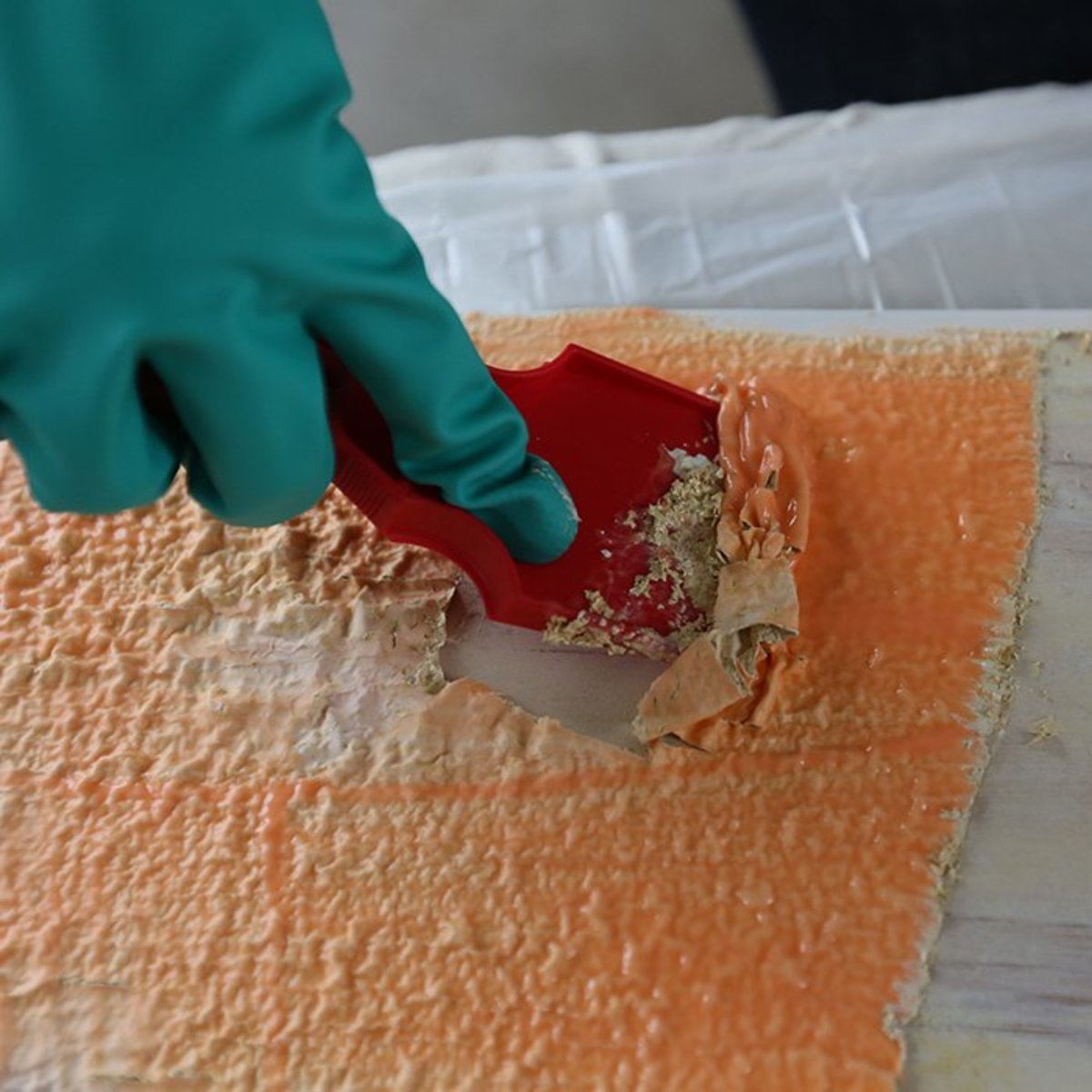

Chemical Deglossers

Chemical deglossers are specialized solutions designed to remove gloss from wood surfaces. They work by breaking down the glossy finish, making it easier to remove.

Application Methods for Chemical Deglossers

- Apply with a Brush or Cloth: Most chemical deglossers are applied with a brush or cloth. Follow the manufacturer’s instructions for application time and drying time.

- Use a Spray Bottle: Some deglossers can be diluted and applied with a spray bottle. This method is often preferred for larger surfaces or areas with intricate details.

- Follow Safety Precautions: Always wear gloves and eye protection when using chemical deglossers. Work in a well-ventilated area and avoid contact with skin or eyes.

Sanding vs. Chemical Deglossing, How to degloss wood cabinets

Sanding and chemical deglossing are both effective methods for deglossing wood cabinets. However, they have distinct advantages and drawbacks:

Sanding

- Advantages: Provides precise control over the level of deglossing, can be used on various wood types, environmentally friendly.

- Drawbacks: Time-consuming, can create dust, requires multiple sanding steps.

Chemical Deglossing

- Advantages: Faster than sanding, less dust, can remove gloss from hard-to-reach areas.

- Drawbacks: Can damage delicate finishes, requires careful application, may have strong odors.

Preparing for Refinishing

How to degloss wood cabinets – Before you begin deglossing your cabinets, it is crucial to prepare the surfaces properly. This ensures a smooth and successful refinishing process, resulting in a beautiful and durable finish. Proper preparation involves cleaning the cabinets thoroughly to remove any dirt, grease, or grime, and patching any imperfections or damage on the cabinet surfaces. Additionally, protecting surrounding areas from the deglossing materials is essential to avoid unwanted damage or staining.

Thorough Cleaning

A thorough cleaning is essential to remove any dirt, grease, or grime that may interfere with the deglossing process. This ensures the deglossing solution adheres properly to the surface, allowing for effective deglossing and a smooth, even finish.

- Start by dusting the cabinets with a soft cloth or brush to remove loose dust and debris.

- Use a mild dish soap solution and a soft sponge to wash the cabinet surfaces, paying particular attention to areas prone to grease buildup, such as handles, doors, and drawer fronts.

- Rinse the cabinets thoroughly with clean water to remove all soap residue.

- Allow the cabinets to dry completely before proceeding to the next step.

Patching Imperfections

Before deglossing, it is important to address any imperfections or damage on the cabinet surfaces. This ensures a smooth and even finish after refinishing.

- Use wood filler to patch any holes, dents, or scratches. Apply the filler according to the manufacturer’s instructions, ensuring it is smooth and level with the surrounding surface.

- Sand the filled areas with fine-grit sandpaper to create a smooth transition between the filler and the original surface.

- For larger imperfections, consider using a wood patch or veneer to repair the damage.

Protecting Surrounding Areas

To avoid unwanted damage or staining, it is crucial to protect surrounding areas from the deglossing materials. This involves covering surfaces and floors with appropriate materials.

- Cover floors with drop cloths or plastic sheeting to prevent spills and splatters from damaging the floor.

- Use painter’s tape to mask off areas you do not want to degloss, such as trim, walls, or countertops.

- If necessary, remove cabinet doors and drawers for easier deglossing and protection of surrounding areas.

Deglossing wood cabinets involves removing the existing glossy finish to prepare the surface for painting or staining. This process is often necessary when updating older cabinets or achieving a specific aesthetic. A popular choice for organization, the white wood 3 drawer file cabinet , may also benefit from deglossing if the existing finish is outdated or damaged.

Deglossing techniques typically involve sanding, chemical strippers, or a combination of both, and the appropriate method depends on the type of finish and desired outcome.

Deglossing wood cabinets involves removing the glossy finish to create a more porous surface for paint adhesion. This process can be achieved through sanding or chemical deglossing agents. If the cabinets are painted, removing the existing paint layer may be necessary before deglossing.

A comprehensive guide on how to strip paint from wood cabinets can provide valuable insights for this step. Once the paint is removed, the wood can be deglossed using appropriate methods to ensure optimal adhesion for the new paint application.